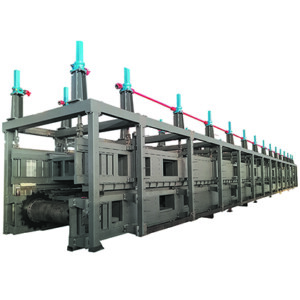

The purpose of the centrifuge is to turn the high-temperature liquid melt flowing onto the high-speed rotating roller into fibers through the action of centrifugal force. The centrifuge is designed in the form of a trolley, and the four wheel.

frames move on the track to facilitate the replacement of the centrifuge. The melt falls on the surface of one roller, andpart of it is sucked by the roller due to the viscous relationship, and the other part is thrown to the other roller under the action of centrifugal force. , split into a thin stream, broken under the action of the surrounding airflow, and solidified into fibers. The melt that is thrown to the other roll is similarly formed into fibers, and so on to the fourth stick. When working, the four rollers of the centrifuge are surrounded by an air ring, and the high-speed gas ejected from the air ring increases the compound drafting effect on the melt, making the fibers thinner and longer, and at the same time sprayed by the glue nozzle. The binder is sprayed evenly on the fibers.

The roller main shaft of the centrifuge is hollow, and cooling water is passed through it for cooling the rollers. The roller.

main shaft bearing is lubricated by oil mist, which is reliable and has the effect of cooling and dustproof. The cooling water and lubricating oil must be passed through before the centrifuge is started; the lubricating oil and cooling water must not be stopped during the operation of the centrifuge. Once the centrifuge fails, first exit the working position, then cut off

the lubricating oil, and finally stop the cooling water.